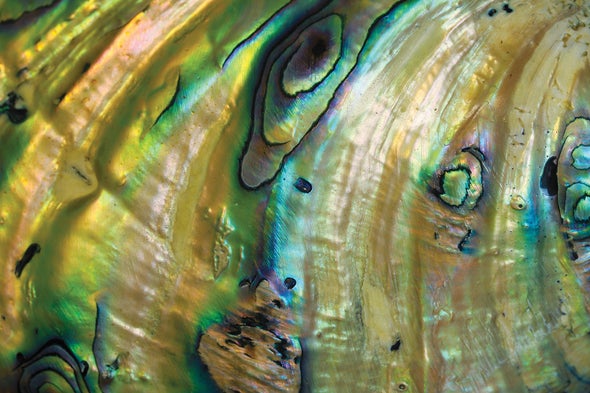

Nacre, an iridescent material that lines some seashells, gains strength and toughness from its structure: brittle mineral chips glued into layers by squishy proteins. Now researchers have used the same principle to develop a superstrong glass composite that could one day make nearly unbreakable smartphone screens, windshields and other items that currently rely on various types of treated glass.

The new material combines rigid glass flakes, less than one hundredth of a millimeter thick, with flexible acrylic. “When we combine those two together, similar to nacre, we recover the best parts of both components,” says Allen Ehrlicher, a McGill University bioengineer and co-author of a recent paper describing the composite, which was published in Science.

Both glass and acrylic are transparent on their own, but light travels through each of these materials at a different speed. As a result, previous attempts to combine them made a substance that was too opaque. So the researchers mixed small quantities of a hydrocarbon with the acrylic until it interacted with light more like glass does.

The result is not only transparent, Ehrlicher says, but also 400 percent stronger and 650 percent more damage-resistant than the material used in car windshields: resin sandwiched between two layers of glass. Plus, the new substance can be cut and drilled with standard tools. Ehrlicher compares the way the acrylic binds the glass flakes into a stacked structure to a brick wall with staggered layers: any crack snaking through the new material will follow the acrylic seams in a convoluted path, thus requiring more energy to fracture. “By forcing it to go through a long path, to break through a lot of this connective material—a lot of this ‘mortar,’ by analogy—we create a material that’s very, very tough,” he explains.

To construct these layers, the researchers spun their ingredients in a centrifuge. The simple technique means “you would be able to do this at scales much larger than what a lot of [other] synthetic nacre can be done at,” says Cornell University materials scientist Lara Estroff, who was not involved in the research. Such ease of manufacturing could enable a variety of applications—eventually. Arun Varshneya, president of Saxon Glass Technologies, points out that the material is still less transparent than glass and more prone to surface scratches. Nevertheless, he says, “I’m actually quite enthused with this gallant effort in the right direction.” Varshneya, who was also not involved in the research, lauds the composite’s strength throughout the material, in contrast to the chemically strengthened glass used in items such as smartphone screens (whose hardening is limited to a thin surface layer).

Ehrlicher says he hopes to keep improving the new material’s transparency and scratch resistance while retaining its remarkable toughness. “Inevitably it’s been a trade-off between transparency and strength, or strength and rigidity, or work of fracture and rigidity,” he says. “And what we’ve created here is the best sweet-spot balance of all of those.”